Fabric Inspection System – Greige Fabrics

- Fabric inspection (Greige) enables digitized fabric quality assurance, automatically calculates fabric grade according to ASTM 4 point system.

- Sort wise, loom wise, weaver wise quality analysis and reporting

- Linkage of Greige defects to final inspection of finished fabrics to produce optimized results

- Weaving Job worker and purchased fabrics realization Reporting, Wastage Reporting, Meter & Weight Reconciliation, Beam Wise Crimps based on Actual receipt

- Integrates with your ERP, Roll wise barcode is printed for fabric traceability.

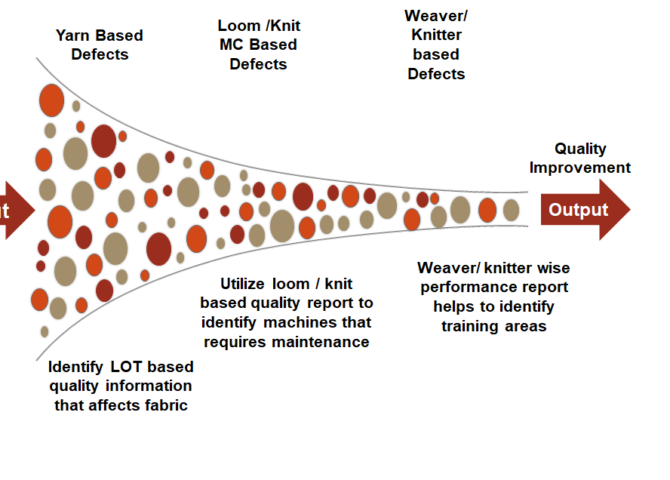

Get 360 Degree view of quality

Right from yarn quality, Loom/Knit machine maintenance, weaver training, daily inspection production, vendor analysis, crimps reporting etc.,

CAPA

FIDAS instant reports with analytics would help you in every day Corrective & Preventive actions (CAPA) meetings without wasting time

Analytics

Order based profitability, defect analysis, fabric realization and wastage analysis helps you by data driven business and assist you in decision making.

Labour Saving

All operations right from fabric receipt from loom shed into inspection shed till your packed fabric zone would be automated by FIDAS. No manual entry of data and 100% error free data assured.

LEARN MORE ON GREIGE FABRIC GRADATION

CONTACT US FOR GREIGE FABRIC GRADATION REQUIREMENTS

FIDAS – Knitted Fabric Inspection Module

- Knitted fabric during final assesment need to adhere to quality requirements of garmenting units such as declaration of minimum width and width measurement at every 15 meters

- GSM verification for every roll from real GSM cutter to actual roll weight and width tally

- Real-time GSM verificaion while production no wastage of time

- Online Recording of defects and calculate point per 100 square meter / yards as per ASTM 4 point system ensure no fabric returns and debit notes

- Purchased Fabric Quality Analysis and vendor analysis Realization Reporting, Wastage Reporting Meter and weight Reconciliation

Reports

Shift wise production, realization, GSM, Width, style wise production and analytics roll to GSM Tally reports

Directly From Compacting

FIDAS Software can be implemented directly on your compacting machine without wasting your time for separate inspection machine

Barcode / QR Code

Style wise / Roll Wise quality and roll number generation & length, Width, weight and GSM data would be printed on real-time basis without interrupting production.

Defend Customer Claims

FIDAS provides instantaneous reports to defend your customer claims and debit notes.

LEARN MORE ON KNITTED FABRIC INSPECTION

CONTACT US FOR YOUR KNITTED FABRIC INSPECTION REQUIREMENTS

FIDAS – Denim Fabric Inspection & Optimization

Denim fabric inspection is different from other fabrics whereas inspection plays a critical role in the profitability of the organization. However, inspection department of denim fabric manufacturing companies are seen as profit centers rather than cost centers thanks to FIDAS implementation.

- FIDAS is the only software in the world which inherits within roll optimization feature. So that dual inspection is avoided.

- Our batch optimization algorithm is rated best among other similar optimization software across the globe

- Concentration on quality improvements

- Every panel cut is tracked back to rolls and quality ascertained using FIDAS software

Avoids 20% Wastage

FIDAS assures you with min 20% wastage. This means your profitability would be increased by 2% -5%. This has been proven in various implementations in the past.

Real-time Optimization

FIDAS software so unique in such a way that fabric optimization happens during inspection. FIDAS acts as a watch dog and never ever allow fresh fabric to go within lower grades.

ReaL-time Alerts

Real-time alerts given to fabric checkers while fabric turns to lower grades and suggest / guide them for fresh fabric cutting.

Two Piece joining

FIDAS assists the fabric checker to join rolls within 200-400 meters with the big roll and makes short pieces to fresh by providing best in class piece joining option.

LEARN MORE ON DENIM FABRIC INSPECTION

CONTACT US TO MAXIMIZE FRESH FABRIC REALIZATION

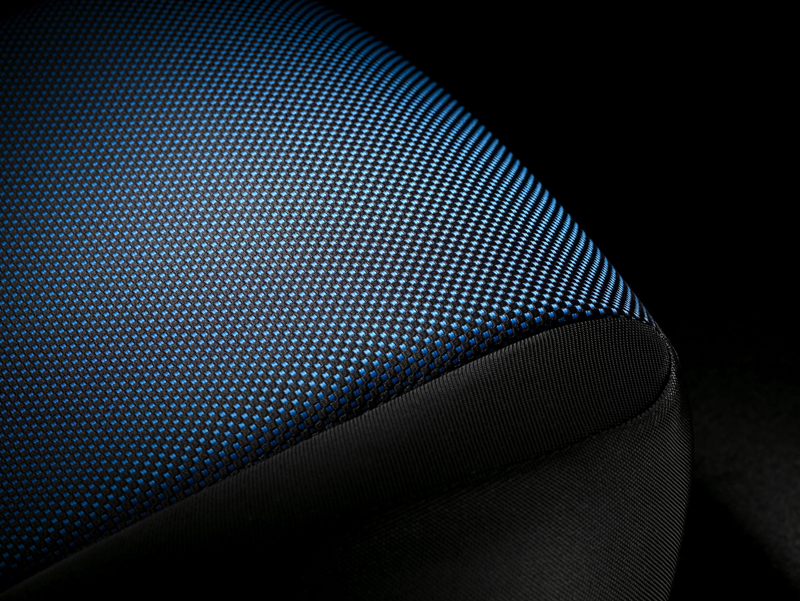

FIDAS – Automotive Seating Fabric Inspection

- Quality verification starts from loom / warp knitting production where the defects are identified and mended at Greige stage and these defects are tracked back in final inspection.

- Processed fabric is inspected again to identify process based defects before lamination

- Foam thickness is measured meter by meter automatically during lamination

- Automatic Assignment of compensation meters to the buyers and FIDAS ensures adherence quality norms

- Every panel cut is tracked back to rolls and quality ascertained using FIDAS software

Fresh fabric

Greige fabric inspection for loom & warp knit fabrics

Quality

Measurement

Real-time foam Thickness measurement

Net Realization

Automated cut-plan creation for final inspection and increase in net realization

LEARN MORE ON AUTOMATIVE FABRIC INSPECTION

CONTACT US FOR YOUR AUTOMATIVE FABRIC INSPECTION REQUIREMENTS

FIDAS – Home Furnishing Fabric Inspection

Home textiles fabric inspection concentrates more on utility based categorization of end use. The cut plan is generated based on defects on the fabric and creating cut plan in accordance to the end use.

- FIDAS helps you to automatically grade the fabric in accordance style number and fabric type as specified by each and every brand.

- FIDAS helps to ascertain whether this fabric need to be sent for further processing or 100% inspection required.

- Integrated camera in FIDAS provides evidence for creating debit notes or internal quality approval purposes

Quality Information

FIDAS provides defect location information for lay and cutting table.

Quality

Shade grouping information would be provided by FIDAS for every roll inspected.

Alerts

Real-time alerts in case of quality downgrade

Piece joining

Best in class piece joining option

LEARN MORE ON HOME FURNISHING FABRIC INSPECTION

CONTACT US FOR YOUR HOME FURNISHING FABRIC INSPECTION REQUIREMENTS

FIDAS –Fabric Inspection for Readymade Garment Units

Any apparel manufacturing unit required to inspection multiple variety of fabrics and each variety need to inspected and graded accordance to fabric type and by the specification given by merchandizer or brand owner.

- FIDAS helps you to automatically grade the fabric in accordance style number and fabric type as specified by each and every brand.

- FIDAS helps to ascertain whether this fabric need to be sent for further processing or 100% inspection required.

- Integrated camera in FIDAS provides evidence for creating debit notes or internal quality approval purposes

Fresh fabric

Minimum 20% wastage avoidance, which means extra fresh fabric realization

Quality

Customer based quality adherence

Alerts

Real-time alerts in case of quality downgrade

Piece joining

Best in class piece joining option

LEARN MORE ON READYMADE GARMENTING INSPECTION

CONTACT US FOR YOUR READYMADE GARMENTING INSPECTION REQUIREMENTS

Facebook

Youtube

Linkedin

Whatsapp