Greige Fabric Inspection Software

- Fabric inspection (Greige) enables digitized fabric quality assurance, automatically calculates fabric grade according to ASTM 4 point system.

- Sort wise, loom wise, weaver wise quality analysis and reporting

- Linkage of Greige defects to final inspection of finished fabrics to produce optimized results

- Weaving Job worker and purchased fabrics realization Reporting, Wastage Reporting, Meter & Weight Reconciliation, Beam Wise Crimps based on Actual receipt

- Integrates with your ERP, Roll wise barcode is printed for fabric traceability.

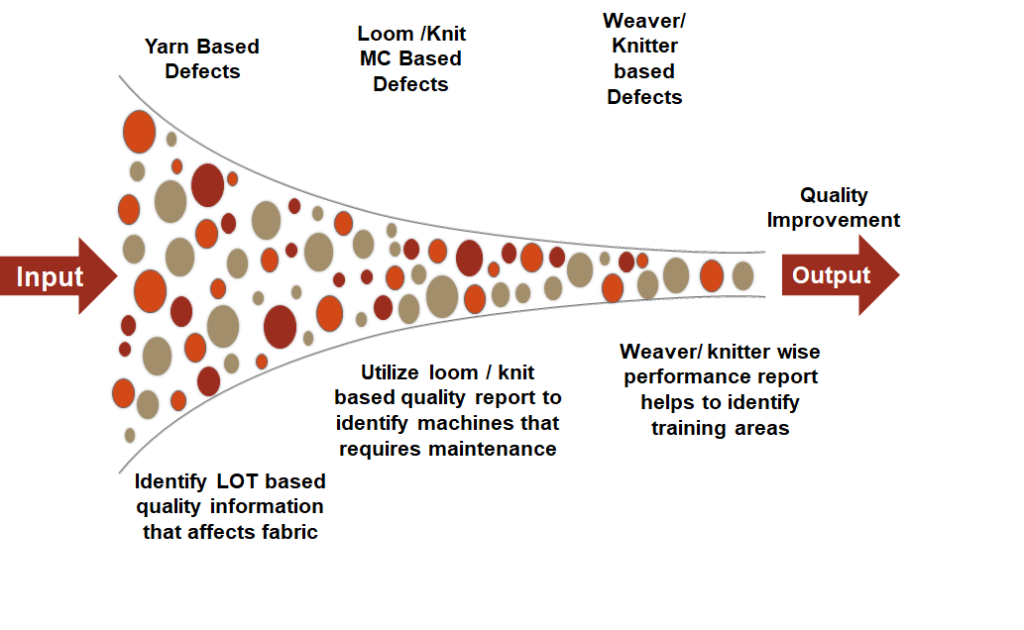

Get 360 Degree view of quality

Right from yarn quality, Loom/Knit machine maintenance, weaver training, daily inspection production, vendor analysis, crimps reporting etc.,

CAPA

FIDAS instant reports with analytics would help you in every day Corrective & Preventive actions (CAPA) meetings without wasting time

Analytics

Order based profitability, defect analysis, fabric realization and wastage analysis helps you by data driven business and assist you in decision making.

Labour Saving

All operations right from fabric receipt from loom shed into inspection shed till your packed fabric zone would be automated by FIDAS. No manual entry of data and 100% error free data assured.

Benefits derived by implementing FIDAS application in your company

FIDAS helps to Improve Production in Inspection Department

- Faster Defect Logging

- Improves worker efficiency as no need for manual marking in paper

- No manual defect re-entry in ERP System

- Get reasons for non-productive time

- Reduced Roll Doff time

- Real-time online monitoring of inspection production

- Automated Grade Generation

- Set quality targets such as EPI, PPI, Width and GSM variation

- Easy to fix increased production target.

FIDAS pre-empts for Corrective Actions

- Defects acquired in Software are segregated in accordance to departments where they occurred

- Reasons for defects should be analyzed and can be corrected at utmost priority

- Style Wise/ Day Wise / Department Wise Defect Reports Generated

- Production Departments are debited for Wastages

- Impose responsibility on production teams

FIDAS helps you to minimize defects & maximize the realization

- Accomplish processes that cannot be done manually

- Each Fabric Roll Inspected has Unique Grading specification based on

- Customer, Fabric Type, Application

- Passing this information to each inspector would be a tedious task

- But FIDAS automatically acquires these quality Specifications from ERP

- Actual Vs Calculated weight Verification (Alerts in case of Deviation)

- Calculation of Demerit Points as per ASTM 4 Point System

- Gradation in accordance with every customer Quality Specifications

- Grades are automatically calculated as specified in Order

- Barcode Printed as per Order

Eliminate routine manual and clerical tasks

- Manual Defect Logging – Eliminated

- Manual Generation of Excel Reports – Eliminated

- Data entry operators minimized

- No erroneous data

- Manual identification of Rolls meant for delivery – Eliminated