FIDAS - FABRIC INSPECTION SOFTWARE

FIDAS - FABRIC INSPECTION SOFTWARE

Fabric Inspection & Defect Analysis System (FIDAS) fabric inspection software has become a big asset within the field of quality control. FIDAS software is specially designed to register defects detected on fabric inspection frames, saving the operator many issues further down the production line.

Key Features

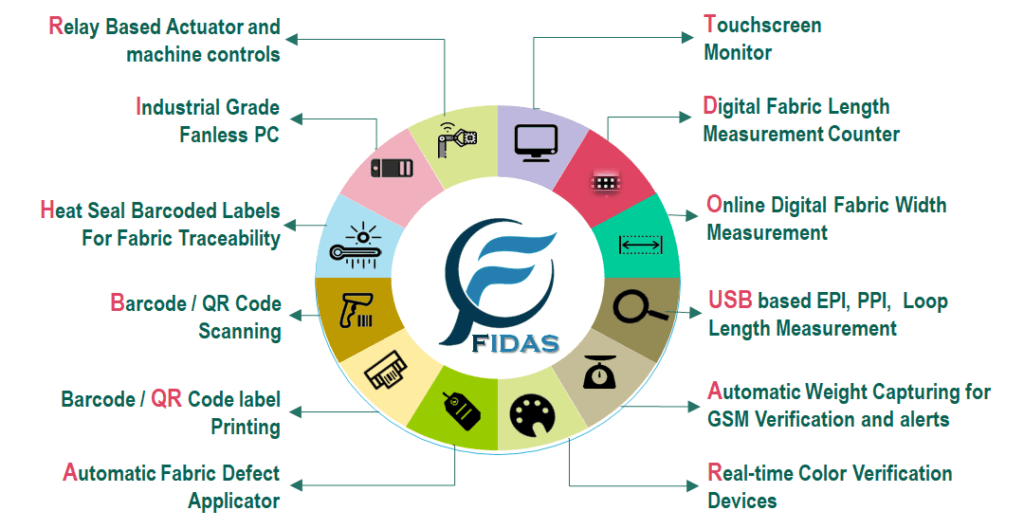

FIDAS software features a high-end 15" touch panel P, complete with a graphical and intuitive, real-time gradation. This facilitates a user-friendly interaction with the inspector. Interfaced with the length counter, weighing scale, tagging device and other peripheral equipment.

The software can be used in two ways:

- Combined with the on-loom, grey and finished fabric inspection and cutting system

- As a stand-alone terminal, to assist the manual inspection process, calculate the grade and print piece maps and labels

FIDAS Software Features

- Order and piece information, including inspection instructions download from enterprise resource planning (ERP) system

- Entry facility for defect codes, referencing elements including severity, width and position

- Entry facility for notes and additional quality parameters, such as weight, width and shade

- Real-time piece map and defect concentration graph

- "Grade assistant" for real-time advice about the reasons for "off-quality"

- Import of defect maps and defect pictures for re-inspection/mending activities

- Front and back inspection, cutting and multi panel support

- Fully configurable user interface

- Foreign language support and on-screen language selection

- Ethernet connection an ERP system

- Interfaces for machine run/stop and speed control, printer, scale, barcode scanner and keyboard

- Length-counter interface for automatic length registration

Conclusion

FIDAS software is transforming the fabric inspection process, making it more efficient, accurate, and user-friendly. By implementing this advanced software, textile manufacturers can significantly improve their quality control processes, reduce errors, and ultimately deliver higher quality products to their customers.