FIDAS SOP: Comprehensive Guide to Fabric Inspection and Defect Analysis

FIDAS SOP: Comprehensive Guide to Fabric Inspection and Defect Analysis

Introduction

Fabric mills should perform 100% inspection before sending any consignment to the apparel industry to minimize hassles. This Standard Operating Procedure (SOP) outlines the key considerations, processes, and systems used in fabric inspection, with a focus on the widely-adopted Four Point System.

Key Considerations for Fabric Inspection

A. Inspection Environment and Equipment

- Area: The inspection area should be dry, open, clean, and cool with sufficient light.

- Equipment:

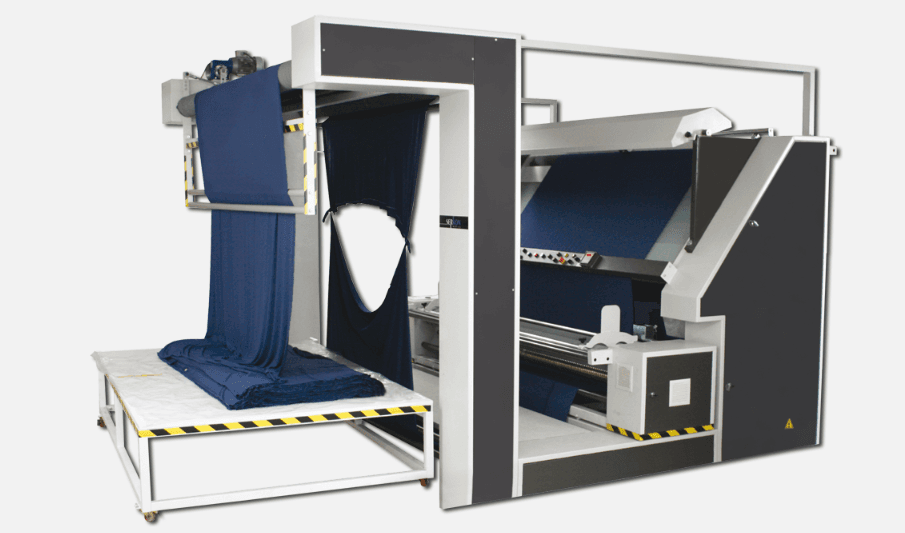

- Both garment makers and fabric mills should have high-quality inspection equipment.

- The inspection equipment should be smooth, fresh, user-friendly, and free from sharp edges that could scratch the fabric.

- Accessories: Essential accessories include:

- Measuring tape

- Scissors

- Defect stickers or chalk

- Fabric defect display board

- Reference samples

- Blank inspection forms

B. Operation, Findings & Actions

- Viewing Distance: Inspectors should maintain a distance of 2 to 3 feet for optimal vision of the full fabric width.

- Inspection Speed: The speed should be adjusted based on the inspector's capability and the nature of the fabric being scrutinized.

- Lighting: Proper lighting is crucial for accurate defect detection and rating.

- Inspection Process:

- Roll selection

- Proper fabric positioning

- Thorough checking for defects and discrepancies

The Four Point System

The Four Point System is the most popular and widely used method for fabric inspection due to its simplicity and effectiveness.

Why the Four Point System is Preferable

- It's simple to apply, educate, and learn.

- It's certified by the American Society of Quality Control (ASQC) and the American Apparel Manufacturers (AAMA).

- It provides a standardized method for assigning penalty points based on defect severity.

How the Four Point System Works

- Defects are classified based on their size and severity.

- Penalty points (1-4) are assigned to each defect.

- The total points per 100 square yards of fabric are calculated.

- Fabric with more than 40 points per 100 square yards is considered second quality.

Conclusion

Implementing a robust fabric inspection process using the FIDAS SOP and the Four Point System can significantly improve quality control in textile manufacturing. By following these guidelines, both fabric mills and garment manufacturers can minimize defects, reduce waste, and ensure higher customer satisfaction.