Automotive Panel Traceability & Packaging System

Solution Overview

APTAPS monitors automotive panel production from source fabric roll to final packaged master cartons. Panels are verified via FIDAS, uniquely barcoded, tracked through LDPE bundles and master cartons. Real-time ERP integration ensures accurate inventory, invoicing, and complete end-to-end traceability, preventing packing errors and reducing manual reconciliation.

Objectives

Achieve Complete Traceability

Establish a digital trail linking each panel to its source fabric roll, ensuring full visibility for quality control, audits, and recalls.

Eliminate Manual Packing Errors

Automate bundle and master carton validation to prevent mixing of different panel types, sizes, or lots during packing.

Reduce Data Discrepancies

Synchronize packing and stock data directly with ERP in real time to eliminate mismatches and reduce manual reconciliation efforts.

Highlights

End-to-End Traceability

Achieve full panel traceability from source roll to master carton.

Quality Gate Enforcement

Only panels approved via FIDAS/QC enter packing workflow.

Automated Packing Rules

Same-sort panels per LDPE bundle & master carton.

ERP Integration

Seamless real-time stock and invoicing updates.

Accurate Tracking

Track WIP, LDPE bundles, and master carton contents accurately.

Reduced Operator Errors

Minimize mistakes and improve overall production efficiency.

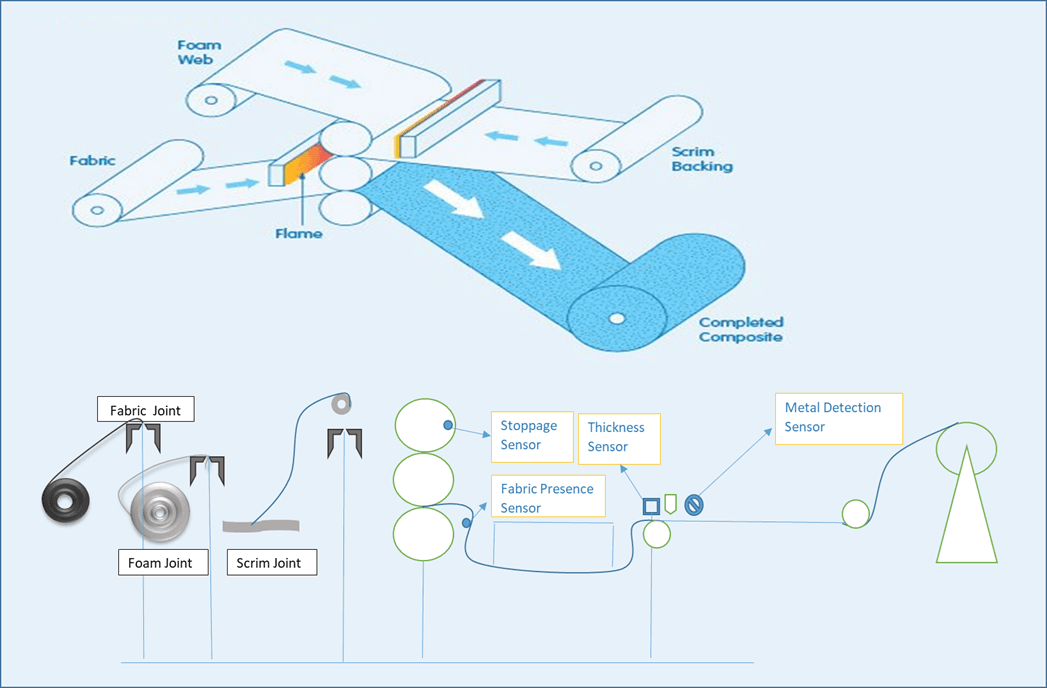

System Workflow

Panel Scanning

Panels are scanned and verified via barcode for traceability.

Bundle & Carton Packing

Panels grouped into LDPE bundles and master cartons as per rules.

Barcode Printing

Unique barcodes printed for panels, bundles, and cartons.

ERP Sync

Packing and stock data updated in ERP in real time.

Panel Scanning

Panels are scanned and verified via barcode for traceability.

Bundle & Carton Packing

Panels grouped into LDPE bundles and master cartons as per rules.

Barcode Printing

Unique barcodes printed for panels, bundles, and cartons.

ERP Sync

Packing and stock data updated in ERP in real time.

Benefits

End-to-End Traceability

Every panel tracked from source fabric roll to master carton, ensuring compliance and easy recall management.

Quality Gate Enforcement

Only panels passing QC/FIDAS are barcoded and packed, eliminating defective panels from shipment.

Accurate Packing

Automated rules ensure only panels of the same sort/dimensions are packed together.

ERP Integration

Real-time updates of stock and invoicing reduce manual errors and streamline operations.

Reduced Errors & Waste

Minimizes operator mistakes, scrap, and disputes, improving overall efficiency.

Operational Insights

Track WIP, bundles, and cartons for complete visibility into production and packaging KPIs.

Related Solutions

Explore other solutions

Greige Fabric

Knitted Fabric

Processed Fabric

Denim Fabric

Automotive Fabric

Home Textiles

Apparel Manufacturing

Want to improve panel traceability and packing accuracy?

Request a pilot — we’ll help integrate APTAPS for measurable efficiency and error-free ERP updates.